Image Armor DARK Formula DTG Pretreatment

Details

Image Armor DARK Shirt Formula DTG Pretreatment

Image Armor for Dark Shirts is an new formulation designed for the DTG printing industry. It is easier to apply, easier on your pretreatment machines, increases printability, and improves wash fastness of up to 50% or more than the leading pretreatments currently in the market.

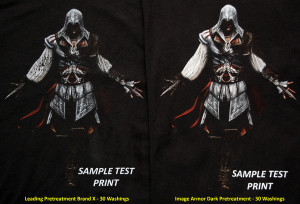

Image Armor Dark is a great improvement over the leading brands. The image above was printed on a 100% cotton Hanes tagless black shirts. The reason we chose this image is it has a lot of subtle detail that fades out, which is one of the hardest details to hold during wash testing.

The shirts were first pretreated with a ViperONE pretreatment machine with the same exact of amount of pretreatment (18 grams for a 14″x14″ area per shirt), and heat pressed using a Hix S650 Autorelease with a pressure setting of 2. The shirts were then cured for 30 seconds until dry. The designs were then printed on a common Epson based DTG printer.

After printing, the shirts were washed in the same washing machine (cold/hot ) and dryer (hot dry) for 30 cycles. Degradation of the image started to appear after the first 5 washings in the Leading Brand X pretreatment. After 30 washing-drying cycles, it is clear there is a significant increase in wash durability of the Image Armor Dark pretreatment vs Brand X.

What This Means to You and Your Customers

One of the biggest issues with direct to garment printing has been washability. Many have been disappointed with the white ink wash fastness of all the direct-to-garment printers on the market. Part of this is relative to the inksets used, however, the foundation for the entire DTG printing process is the application of the pretreatment, and more specifically, the pretreatment chemistry itself. Image Armor is designed from the ground up to be the industry’s best option for improving long term washings of your images. The results speak for itself.

Better wash-fastness means your customers will be happier. And if your customers are happier, that means more sales for you in the long term.

That’s our job. To help you Protect Your Image.

Benefits of Image Armor Pretreatment

- No Pretreatment Stains

- No Crystallization of the pretreatment after pressing

- Much wider margin for application – in reverse to the leading brands the more Image Armor applied actually increases washability.

- Easier on your pretreating equipment. Less clogging issues.

Pre-test prior to any production runs for substrate suitability and performance.

Application:

- When applying pretreatment to the garment, make sure to apply it as evenly as possible (mechanical pretreatment machines are the best).

- Depending on the shirt being pretreated there are some variables to consider on how much to apply.

- A good starting point is 15-18 grams per 14″x14″ area.

- NOTE: 18-26 grams may provide you with better washability and white optical brightness. This is opposite of what other manufacturers recommend. Test to find your best laydown for the garment you are pretreating.

- The heavier the garment, the higher the amount of pretreatment needed.

- The darker the color, the more pretreatment is required.

- The lighter the weight of the shirt, you can usually reduce the amount of fluid applied to the garment.

- The lighter the color of the shirt, less pretreatment is usually required.

- A good starting point is 15-18 grams per 14″x14″ area.

- Always use a high quality garment that is ring-spun with a tight knit weave. The smoother and tighter the weave, the better your final DTG print.

Recommended Curing:

Heat set mmediately after spraying. Do not allow to dry before curing. Heat Set on a heat press at 330F for 30 seconds. Raise heat platen to allow excess steam to escape. Heat press for additional 10 second intervals until dry. Raise the heat platen between each interval to allow steam to escape. Covering the garment with heat resistant glossy kraft paper will minimize the amount of garment sizing and pretreatment buildup on heat platen. It also provides a smoother finish that accepts the White Ink more consistently creating better white coverage.

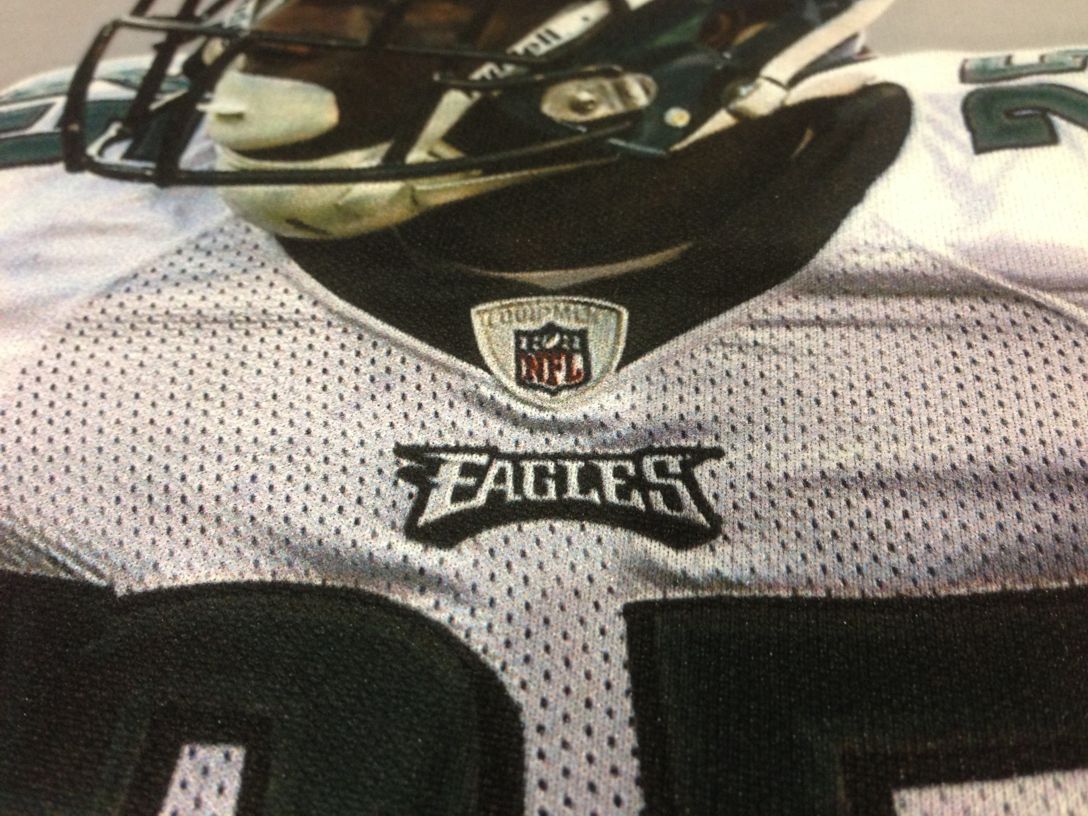

Thanks to some Image Armor Pretreatment beta testers, it has been found that Image Armor Dark Shirt Formula works incredibly well with the new Epson SureColor F2000 direct to garment printer. As can be seen in the picture above, without having been able to test various settings, a user on the T-Shirt Forums was able to post images of the printed shirts utilizing Image Armor Dark Shirt pretreatment formula. With little more than a hunch and some pre-pretreated shirts, Dekay317 was able to post an initial review of the new printer as well as images of shirts printed on Image Armor Dark Shirt Formula.

We welcome Epson to the direct-to-garment printing arena and are excited to be helping advance the DTG printing industry with our new ground breaking pretreatment formula. Image Armor Dark was released at 12:00 pm on Friday September 13th, 2013.

This just in from the NBM Show in Philadelphia (Sept 2013)

The above is 100% polyester performance garment. The pic to the right is a close-up. Although not recommended for 100% polyester color shirts, it seemed to work on these particular colors and shirts. Always run tests before production runs. Excellent print quality, bright colors, high opacity of white. Garments were pretreated using a ViperONE Automatic Pretreat Machine.

What poor pretreatment looks like:

Above image shows the difference between no pretreatment (left side) working into a well pretreated area (right side). This was the result of printing past a pretreated area. You can see what the various stages of pretreatment results reflects in the print. Less and less pinholes as you get to the full pretreated area.

Visit www.imagearmorpt.com for more information and the latest test results!

Need more info? http://imagearmorpt.com/